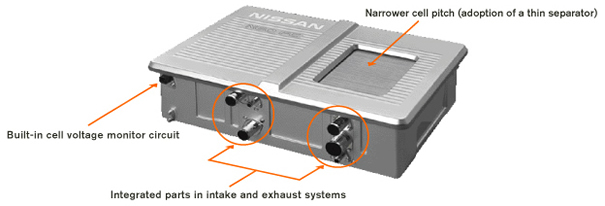

In-house Fuel Cell Stack

Nissan has independently developed its first in-house fuel cell stack, aimed at improving the practicality of fuel cell stacks designed for vehicle application. The first in-house fuel cell stack is featured on the 2005 model X-TRAIL FCV.

Features of Nissan's in-house fuel cell stack

Compact design with high power output.

Nissan's fuel cell stack features a newly developed thin separator*1, a cell pitch*2 that is 40% narrower than before, integrated parts in the air intake and exhaust systems and a built-in cell voltage monitor, all of which contribute to its smaller size. Thanks to these and other improvements, the stack achieves exceptionally high power output for its volume and weight.

Long life

Improvements made to the electrode materials more than double the service life compared with Nissan's previous fuel cell stack.

Improved drivability

The polymer electrolyte membrane*3 and gas diffusion layer (GDL)*4 have been improved to provide quicker start-up and shutdown response, while maintaining the power output characteristic required for vehicle use.

- This component separates the hydrogen and oxygen gases supplied to the individual cells and transfers the electricity produced to the next cell.

- Pitch refers to the spacing between adjacent cells that are connected in series. A stack for vehicle application normally uses several hundred cells connected in series to obtain the necessary electrical voltage.

- This ion-exchange membrane made of a polymer material allows hydrogen ions (protons) produced in the cells to pass through the membrane to the other side.

- This porous material diffuses supplied hydrogen and air, and distributes them to the electrode layer homogeneously.

Fuel cell unit configuration

Specifications

| Type | Polymer electrolyte membrane (PEM) FC |

|---|---|

| Output | 90kW |

| Other | Waterproof and dustproof specification |