Ultra-low Friction Diamond-like Carbon

Nano-technology based ultra-low friction technology

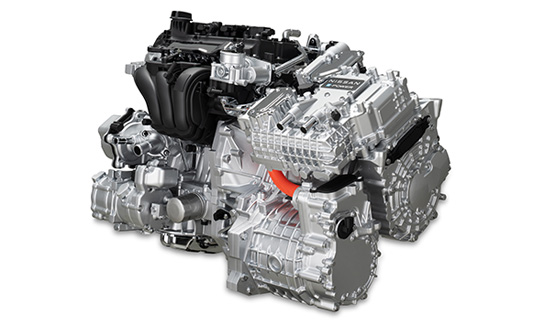

Nissan has substantially reduced friction between engine parts by developing the first technology in the world to combine a hydrogen-free diamond-like carbon (DLC)*1 coating with special oil. Energy is lost due to friction that arises between the hundreds of parts that comprise an engine. This ultra-low friction technology uses nanotechnology in order to reduce friction.

Reduces friction by approximately 40% compared to conventional engines, by forming an ultra-low friction film of nanometer*2 level thickness on top of the hydrogen-free DLC coating.

- DLC (diamond-like carbon): A hard film made of carbon which has diamond-like properties. It has superior abrasion resistance and a low friction coefficient. One hundred millionth of a meter

How it works

Use of a hydrogen-free DLC coating improves binding with the engine oil and results in the formation of a firm ultra-low friction film when special oil additives are added.

It is now possible to reduce overall engine friction by 25% by applying the technology to the parts shown below.