Evolving Supplier Quality

Through our total management system,

we ensure supplier quality on a global basis and down to the smallest detail.

As we build true partnerships with suppliers, supplier quality evolves and improves.

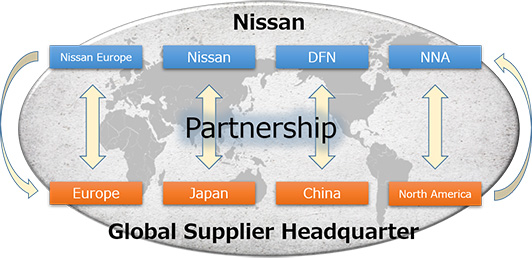

Improving the relationship between Nissan and its suppliers requires the construction of a management framework based not only on Nissan’s demands but also on opinions from suppliers. To that end, Nissan holds regular global quality conferences along with suppliers. At these conferences, top suppliers representing Europe, China, North America and Japan gather together and share information about the quality situation across the world. Through vigorous exchange of opinions, participants explore future management challenges.

Ensuring quality in new areas including electrification, autonomous driving and connectivity

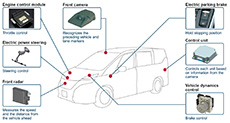

Nissan is promoting vehicle electrification and striving to provide more customers with advanced driver assistance and intelligence technologies as it further enhances the value of these technologies. Due to the introduction of these advanced technologies, the components that make up a car become more complex every year. In order to maintain cutting-edge skills and ensure quality at all times, we have established specialized teams for areas such as electric powertrains and electronic components, bringing our in-house knowledge together under one organization. We are also pursuing quality in new areas by collaborating with our suppliers. For example, we share case studies not only of supplier process activities but also our own gemba in-house manufacturing.

ProPILOT

Examples of ProPILOT components

In-house manufacturing process for electrified vehicle components