Thinking towards the future is something Nissan has always been proud of. At the core of our forward-thinking attitude are the inquisitive minds of our people – particularly researchers like those featured in this story. These bright young individuals challenge themselves day in and day out, chasing their dreams and solving problems. Driven by the core Nissan principle of "Dare to do what others don't", our young researchers push boundaries in their search for solutions to complex problems. Based at the Nissan Research Center, they work at the very cutting edge to develop future technologies for use in the cars of tomorrow.

The Nissan Research Center

The Nissan Research Center is located across two sites in Kanagawa Prefecture. The older of the two buildings dates back to 1958, a hint of just how long Nissan has been investing in R&D. It is here that a lot of Nissan’s technological development begins, providing solutions that will prove essential a decade into the future. The key objective for those involved is to develop advanced technologies leading to practical applications for Nissan. This involves identifying trends and analyzing future needs.

The process can be divided into four focus areas:

- Driving electrification toward carbon neutrality

- Developing mobility services for new value creation

- Expanding AI utilization beyond cars and into production

- Innovating production technologies for vehicles of the future

The research center serves as a compass for Nissan. It is a meeting-point for researchers bound by the same inner drive to change the world via new-value technologies.

Talking to the Researchers

We conducted a series of interviews with young researchers in some of the most up and coming fields.

Living in a microscopic world: Creating the ideal metal powder

3D Printing: Moe Mekata (3 years with Nissan)

Moe Mekata is a 3D printing materials researcher. We asked her about her passion for inquiry and the excitement she gains from developing Nissan’s 3D printing capabilities.

Since her university days, Moe has been interested in production technology. She decided to join Nissan, rather than other manufacturers in different industries, because car production involves a variety of manufacturing processes.

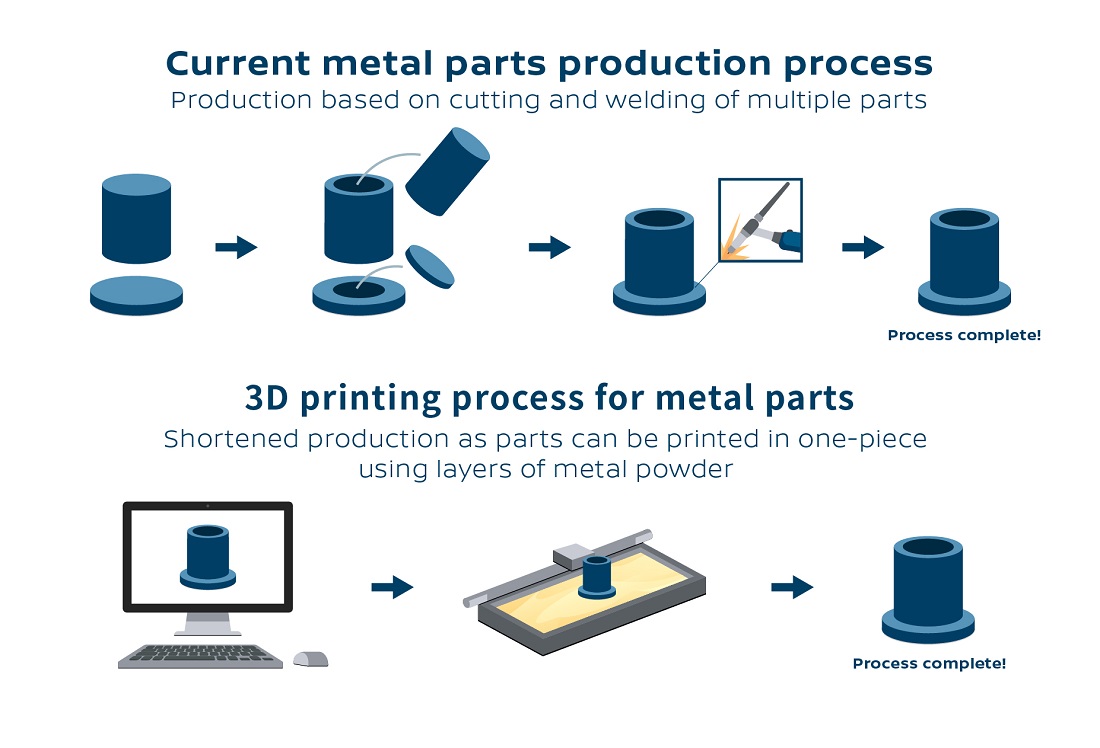

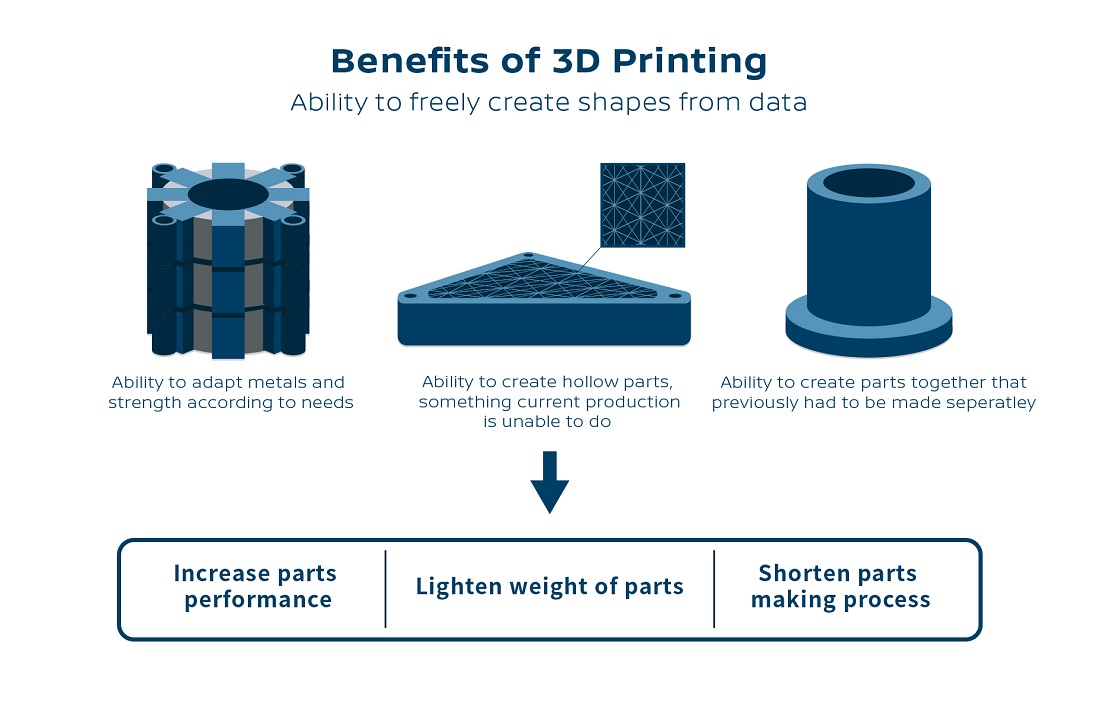

With a sparkle in her eye, Moe tells us that “making metal parts with 3D printers changes the world of car manufacturing. This is because 3D printers can produce parts of any shape without a mold. This allows us to reduce weight by utilizing a 3D structural model and component integration. In addition, 3D printers enable us to vary the strength of a part or its materials (like aluminum or iron) depending on the part itself or its required performance. It’s a dream! We’ll soon be able to create specific parts as requested by engineers.”

The material used in this kind of 3D printing is metal powder. The grains that make up the powder are piled up, fused layer by layer, and formed into a single piece. Unlike conventional parts production – which requires casting, cutting and welding – this method reduces waste. Moe’s research focuses on the development of the metal powders used in the process. One of the challenges leading up to commercialization is to improve the quality of the powder while keeping costs low.

3D printers have gained attention not only for their efficiency and the improvement of overall production quality. But also because they serve an important role in supporting Nissan’s efforts to achieve carbon neutrality. 3D-printed parts can make electric vehicles (EVs) lighter, and thereby increase driving range. This is especially important because EVs tend to be heavier due to the battery packs they carry. By unifying the parts creation process, which previously relied on a multi-stage method, 3D printers optimize the shape of the part in a single step, reducing waste material.

“It’s the overall powder quality that determines the final performance of the 3D printed parts. That’s why we’re aiming to develop new, high-quality powders that no one else has put into practical use.”

Further popularizing EVs: Aiming for a breakthrough!

All-solid-state batteries: Hiroki Kawakami (7 years with Nissan) – Kazuhiro Yoshino (4 years with Nissan)

All-solid-state batteries represent the next-generation of batteries. Hiroki Kawakami and Kazuhiro Yoshino are working to achieve a breakthrough for the practical application of this new battery technology. Hiroki is collaborating with researchers and students from around the world at Purdue University in the U.S., while Kazuhiro is working with researchers at Nissan Research Center in Japan.

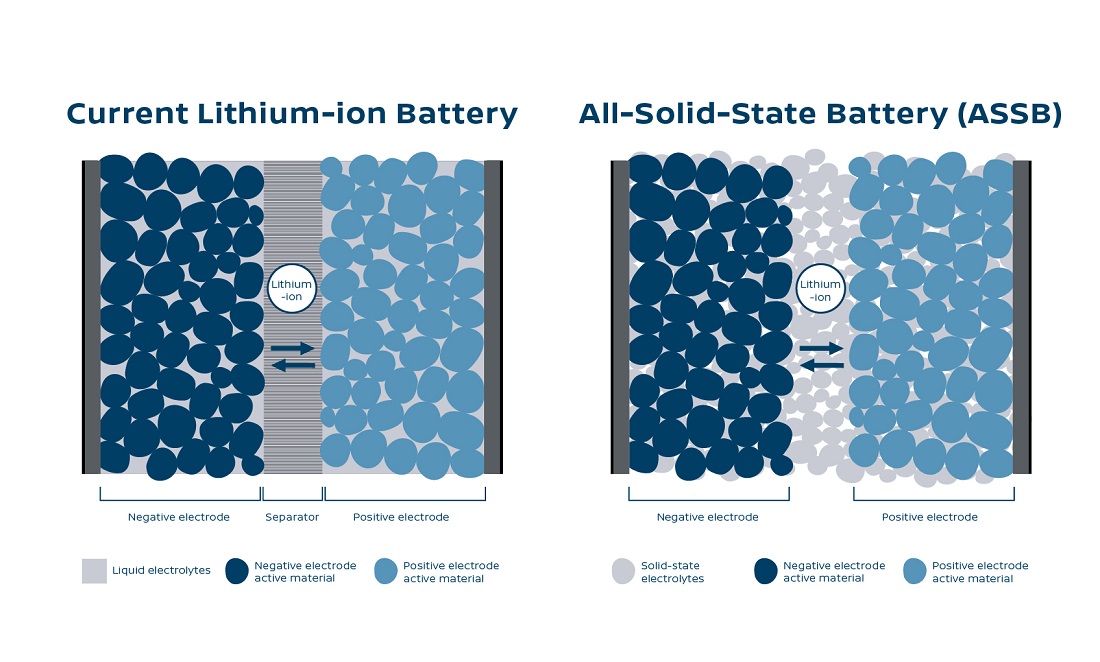

Lithium-ion batteries used in many EVs have a liquid electrolyte that conducts lithium-ion. In contrast, the electrolyte in an all-solid-state lithium-ion battery is – by definition – solid. But why is this new type of battery attracting attention? We asked our two young researchers.

“The biggest advantage of all-solid-state batteries is the significant increase in energy density. By using electrode materials that store more lithium-ion and electrons, more energy can be stored in a smaller volume.” Kazuhiro enthusiastically adds, “If this battery is used in EVs, we can expect dramatically increased range. The solid electrolyte could also make charging faster. For these reasons, all-solid-state batteries will be key in accelerating widespread use of EVs.”

As part of Nissan's overseas assignment program for young researchers, Hiroki conducts daily simulations to investigate what is happening inside the battery and its performance. He sends this information to the Nissan Research Center, where Kazuhiro uses it to make a prototype and test as an actual, physical battery. Together with his colleagues, he conducts experiments to determine if the target performance is achievable.

So, what kind of breakthrough is needed for the practical application of all-solid-state batteries?

"One of the most difficult aspects of developing all-solid-state batteries is the contact between active material particles – which store lithium-ion in the electrodes – and the electrolyte particles – through which the lithium-ion passes," Hiroki says.

“For better contact, we need a machine that applies high pressure from the outside. The key is to ensure sufficient contact, even at low pressure, between the active material of the electrodes and the electrolyte., We’re working hard every day to find a solution to this problem through a process of trial and error.”

With the same enthusiastic sparkle in his eye that we saw with Moe, Hiroki explains: "There are still many things we don't know about what happens inside the battery. To understand it completely, there are a number of issues we still need to solve. We discuss these difficult issues daily with local researchers and students, each of whom have different ways of thinking, and then exchange our views. It’s great when everyone gets on the same page to solve a problem."

Kazuhiro – who has been researching the all-solid-state battery since his university days – thinks that one of the best things about Nissan is that they listen to young people and let them tackle a problem for themselves. “My fellow young researchers and I challenge ourselves every day. Words cannot express the feeling we get when we achieve the performance we are aiming for.”

Within the encouraging atmosphere of the Nissan Research Center, Moe, Hiroki and Kazuhiro will keep on pushing themselves to achieve their aims and deliver future technologies for our customers.