EV competitiveness

Making EVs affordable and profitable

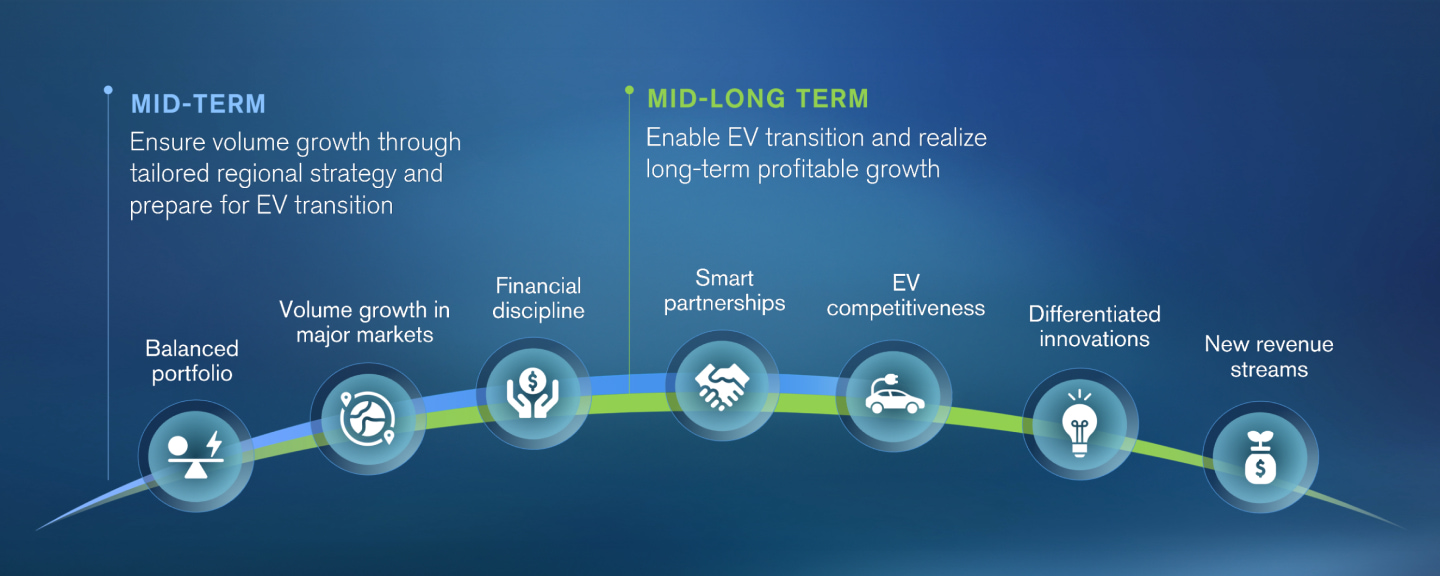

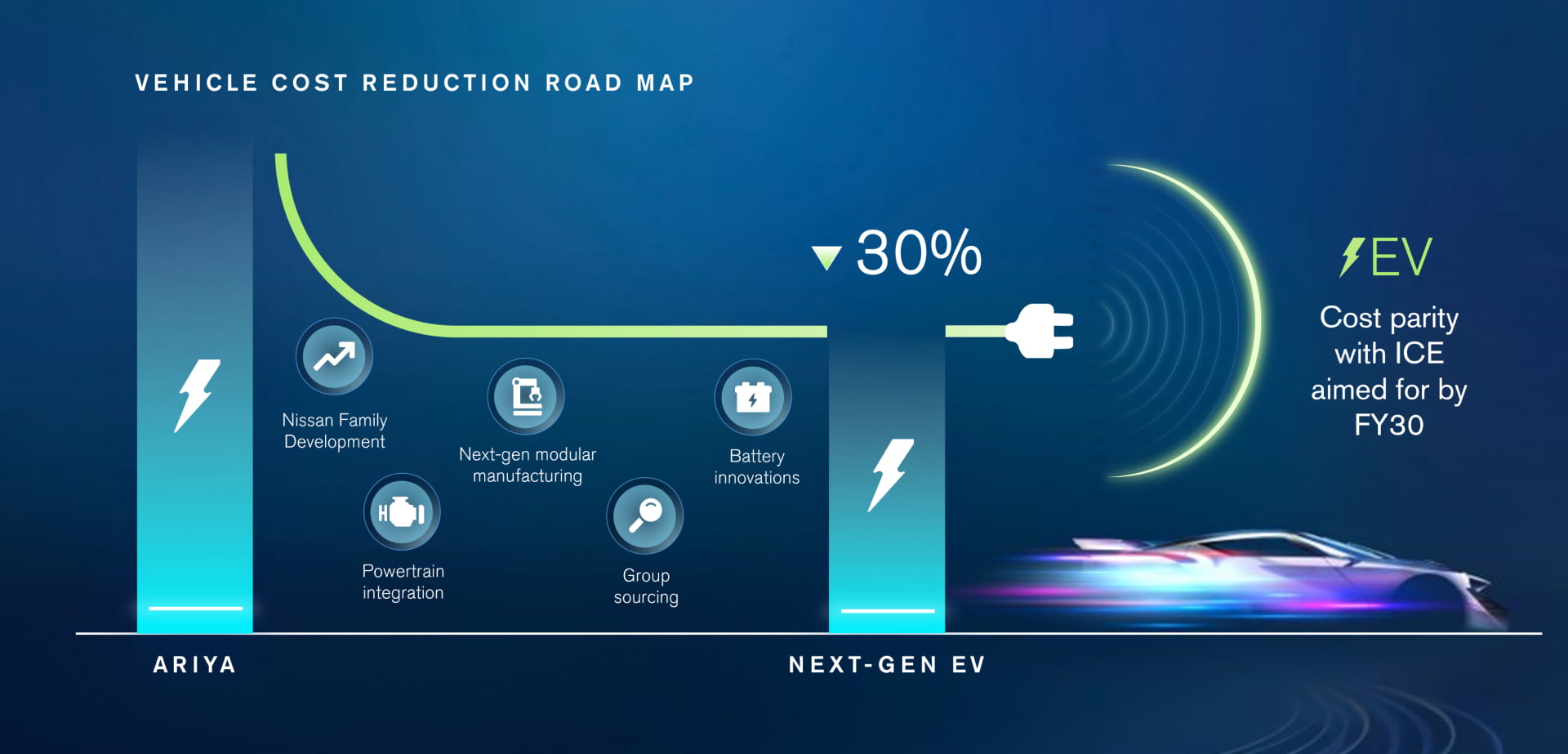

A product offensive will be supported by new development and manufacturing approaches aimed to make EVs more affordable and profitable. By developing EVs in families, integrating powertrains, utilizing next-generation modular manufacturing, group sourcing, and battery innovations, Nissan aims to reduce the cost of next-generation EVs by 30% (when compared to the current Ariya crossover) and achieve cost-parity between EVs and ICE models by fiscal year 2030.

*ICE: Internal Combustion Engine

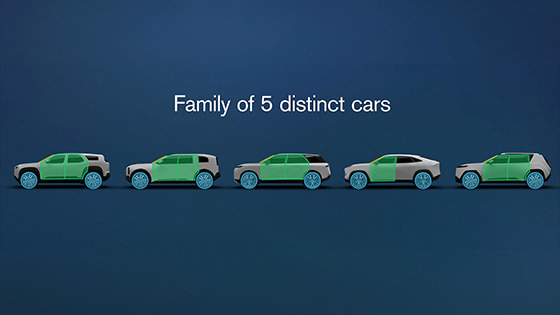

Nissan Family Development

This approach standardizes parts of the upper body for five different models developed as a family, while maintaining unique visual characteristics and attractiveness for each model. By developing five models together, each can share a single, flexible platform that enables the vehicles in the family to cover different segments.

Next-gen manufacturing and resilient supply chain

Nissan's unique next-gen modular manufacturing achieves significant automation and by adopting this production method, the vehicle production line can be shortened, reducing the production time per vehicle by 20% from FY27.

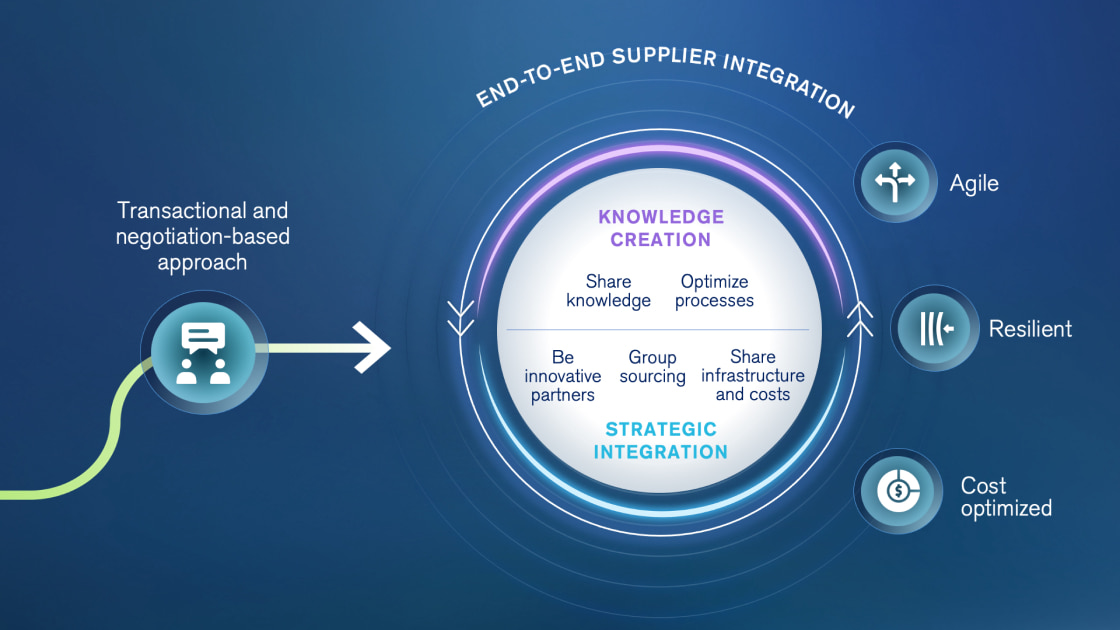

We

will

engage

our

suppliers

in

an

end-to-end

process

-

from

product

planning,

parts

development,

vehicle

development

to

production.

This

will

involve

group

sourcing

of

high-quality

common

components

across

families

of

vehicles

to

reduce

cost-per-unit

and

increase

our

speed

to

market.

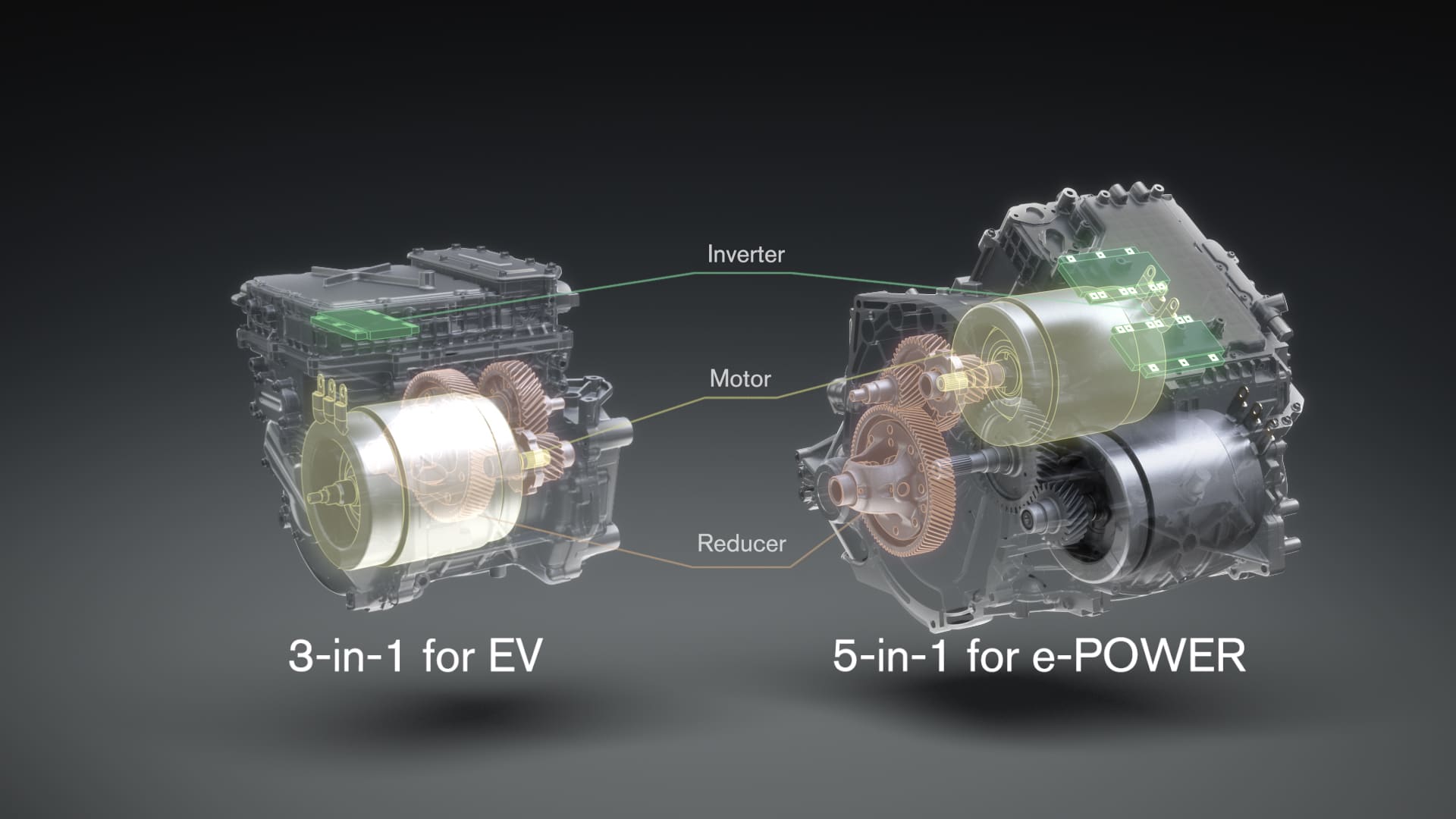

Powertrain integration

Development of the X-in-1 approach will help commonize and modularize our electrified powertrains. These efforts will enable us to develop electrification technologies more efficiently by applying the knowledge gained from EVs to e-POWER and vice versa.

-

3-in-1

for

EVs

Modularize three components (motor, inverter, reducer) -

5-in-1

for

e-POWER

Modularize five components (motor, inverter, reducer, electric generator and increaser)

X-in-1 powertrain integration0:11

Build trust with suppliers

Nissan will develop smarter horizontal relationships with suppliers, bringing them into the process earlier. This will enable us to co-plan and co-develop, share costs and be innovative partners. Importantly, both sides will benefit from the exchange of knowledge, experience and skills, and optimization of processes.

Battery innovations

Nissan will offer enhanced nickel, cobalt and manganese (NCM) lithium-ion batteries, lithium iron phosphate (LFP), and all solid-state batteries to provide diversified EVs to meet different customer needs. Nissan will significantly enhance NCM li-ion batteries, reducing quick-charging time by 50% and increasing energy density by 50% compared to the Ariya. LFP batteries, to be developed and produced in Japan, will be launched that will reduce cost by 30% compared to the Sakura EV minivehicle. New EVs with enhanced NCM li-ion, LFP and all-solid-state batteries will be launched in fiscal year 2028.

Molecule to City: How Nissan is aiming for a sustainable society2:41